An inverter motor or compressor operates from a secondary voltage rather than directly from the mains. A special power board converts the mains voltage into the required voltage for the motor or compressor, allowing it to be precisely regulated within a certain range. This allows the speed and efficiency of the motor to be smoothly regulated.

This technology emerged in the early 2010s and became widespread by the mid-2010s. Its key benefit is the ability to precisely regulate motor speed, which improves the performance of home appliances in a variety of ways – more on this below.

Inverter washing machine and inverter dryer

Inverter motors are widely used in washing machines, though their advantages for users may not always seem significant, as drum speed control is not a critical factor. However, this technology enables the use of brushless and direct-drive motors, which operate more quietly than conventional ones.

Manufacturers often advertise a 10-year warranty on inverter motors, but in practice, this warranty typically covers only the motor itself—not the control and voltage conversion board, which is the core component managing its operation. As a result, users are sometimes surprised when warranty repairs are denied due to board failure rather than motor malfunction.

Overall, inverter washing machines and dryers stand out primarily for their quieter operation, making laundry care more comfortable.

Inverter Refrigerator and Air Conditioner

Inverter compressors in refrigerators and air conditioners operate with a dedicated control board that converts voltage to regulate compressor performance. Unlike conventional models, where the compressor cycles on and off to maintain the desired temperature, inverter-based systems adjust compressor speed instead of shutting it down completely.

This means that in inverter refrigerators and air conditioners, the compressor runs continuously, but at variable speeds. Once the target temperature is reached, the motor slows down to a minimal level—often around 20-30% of its rated capacity—rather than stopping entirely. This approach offers several advantages:

- Energy Efficiency – By eliminating frequent start-stop cycles, power consumption is optimized, leading to lower electricity bills.

- Reduced Wear and Tear – Since there are no sudden power surges or hydraulic shocks at startup, the cooling system experiences significantly less strain, extending its lifespan.

- Stable Temperature Control – Continuous operation ensures more precise and stable temperature maintenance, improving cooling efficiency.

Overall, inverter technology represents a significant advancement over traditional solutions, making refrigerators and air conditioners more efficient, durable, and reliable.

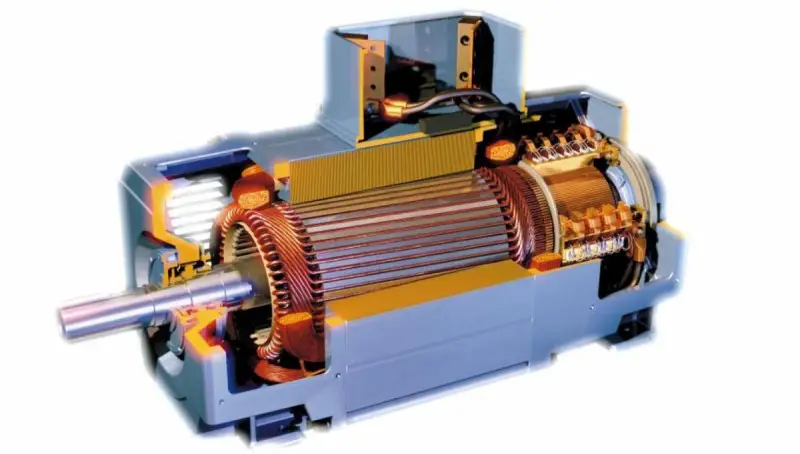

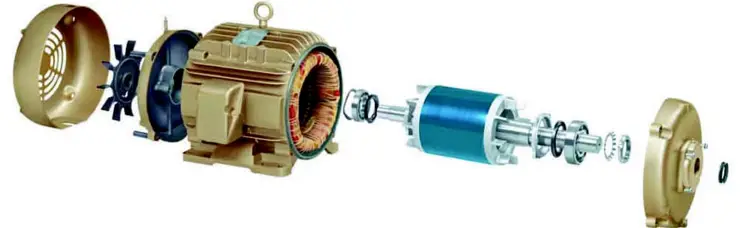

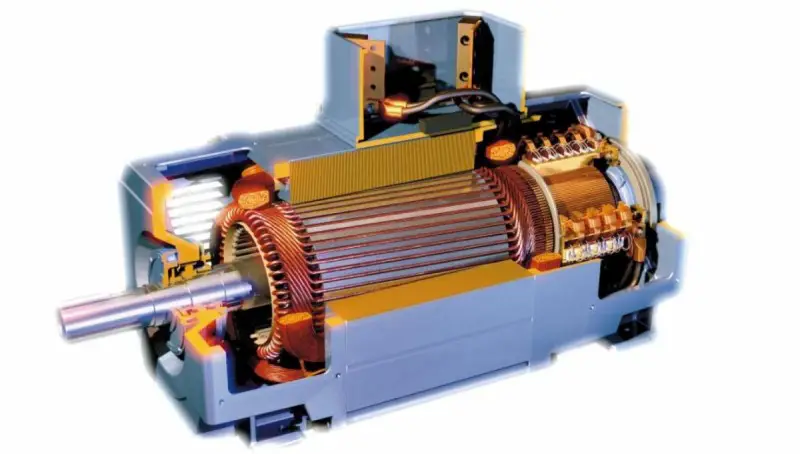

Standard vs. Inverter Motor

Let’s summarize the key differences between standard and inverter motors. Today, almost all household appliances are equipped with inverter motors, primarily because they are easier and more cost-effective to manufacture. This is one of the main reasons why the industry has shifted towards using inverter motors in washing machines. Below is a comparison of both types:

Standard (Classic) Motor

A traditional motor operates using graphite brushes that transfer current to the armature contacts. As electricity flows through the armature winding, it generates a magnetic field, causing the motor to rotate. The stator can consist of either permanent magnets or windings. The motor’s speed and direction are controlled by selectively energizing different windings. Built-in circuitry regulates voltage distribution to achieve the desired speed.

Inverter Motor (Digital Inverter Motor)

In washing machines with an inverter motor, the design is slightly different. Instead of using brushes, the armature operates with static magnets, and the rotation speed is determined by the voltage applied to the stator winding. Importantly, this voltage does not come directly from the mains but is first converted, allowing for precise speed control and more efficient operation.

The inverter motor surpasses the standard motor in several ways. It offers improved energy efficiency, greater durability due to its advanced design, and, most importantly, significantly reduced noise levels. When selecting a washing machine or refrigerator, opting for appliances with an inverter motor is the smarter choice for better performance and longevity.

Inverter motors can also have a belt

So having an inverter motor implies direct drive, or inverter motors can have a belt also?

Motors, very rarely faulty, usually a fault in the control circuit (in the inverter itself). Very often, however, repair shops change the entire motor with the inverter.

Since 2016 GE is bought out by Chinese company Hier. And GE is now 100% Chinese home appliance manufacturer.

Just had the inverter go out in my GE washer that was only two years old with very little use. The price for the inverter is over $500 just for the part so I will not be buying another washer with an inverter.

I agree,lets look at :(inverter drive more cost 15-20% less electricity it consumes but not always) >: -o !????geesh someone needs lessons….