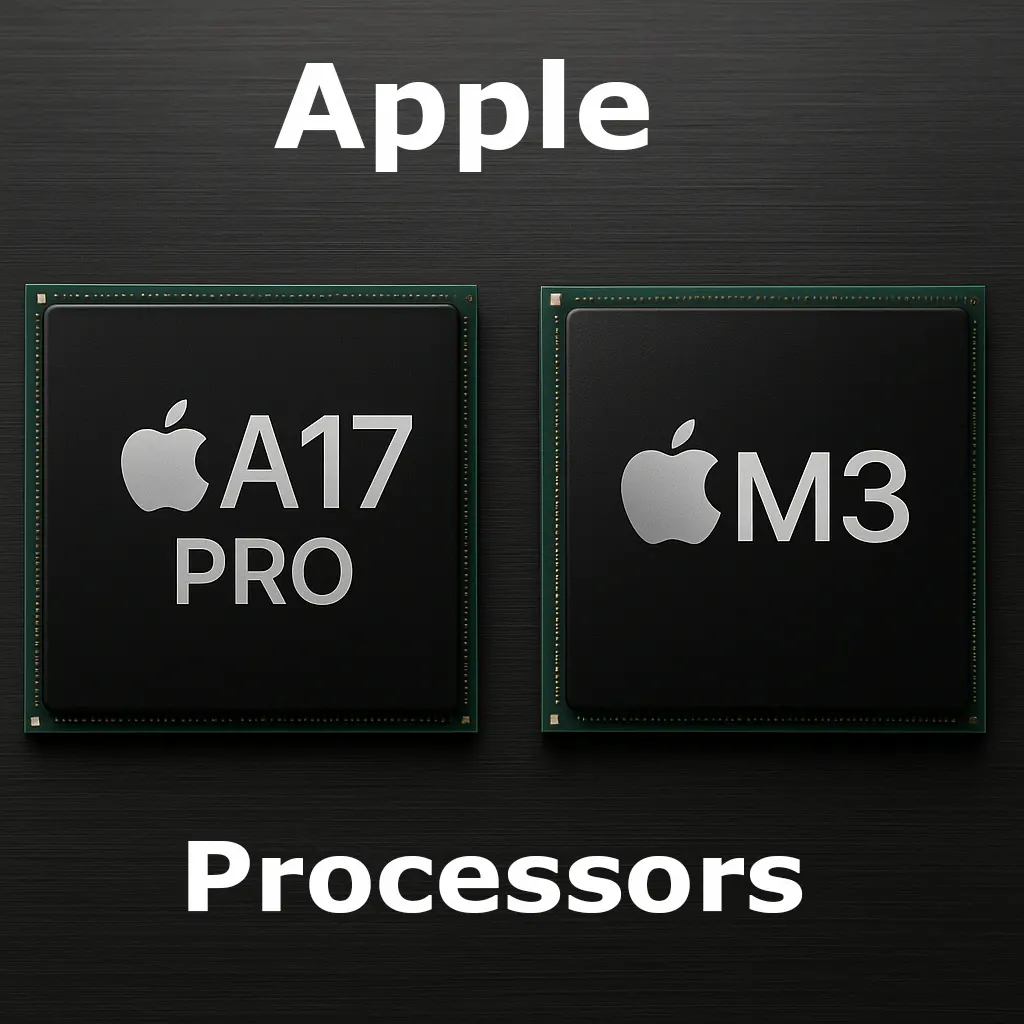

Apple Inc., best known as the developer of the iPhone, iPad, and Mac, does not manufacture its processors independently. Apple’s main role lies in chip design — the company develops the architecture and logical layout of its Apple A-series processors, while physical manufacturing is carried out by specialized contract foundries.

ARM Architecture — The Foundation of Mobile Processors

All of Apple’s mobile processors are based on the ARM architecture (Advanced RISC Machine). This is a set of instructions that defines how the processor handles data and executes commands. ARM is a RISC architecture (Reduced Instruction Set Computing), known for its simplicity and efficiency — qualities that make it ideal for mobile and power-efficient devices.

The ARM architecture is developed by the British company ARM Holdings (now owned by Japan’s SoftBank and partially by Nvidia). ARM does not manufacture chips itself — instead, it licenses its architecture to other companies. Licensees gain the right to use ARM’s instruction sets and core designs (CPU cores), or to create their own solutions compatible with the ARM architecture.

How Apple Designs Its Own Processors

Apple is one of ARM’s licensees. In its laboratories, Apple’s engineers use the ARM architecture as a foundation and develop custom CPU cores and supporting components tailored for Apple devices. Thus, processors in the Apple A-series (A10, A11, A12, A13, A14, A15, A16, and beyond) are not simple ARM clones, but unique Apple-designed chips that remain compatible with ARM instructions.

- Central Processing Units (CPU);

- Graphics Processing Units (GPU);

- Memory controllers;

- Machine Learning systems (Neural Engine);

- Image Signal Processors (ISP);

- Security subsystems (Secure Enclave).

The result is a System on a Chip (SoC) — a single integrated circuit that combines all essential components required for a smartphone or tablet to operate.

Where are Apple processors manufactured?

The primary manufacturer of Apple’s microchips is TSMC, a leading semiconductor company based in Taiwan. All of Apple’s modern processors — from the A-series chips powering iPhones to the M1, M2, and M3 chips used in Macs — are fabricated at TSMC’s advanced facilities. These plants employ cutting-edge technologies, currently at the 3-nanometer level, with 2-nanometer production expected in the near future.

Recognizing the strategic risks of relying solely on Taiwan, Apple and TSMC have taken steps to diversify their manufacturing base. In Phoenix, Arizona, TSMC is constructing a major semiconductor complex that will eventually include six fabrication plants. The first facility, set to begin operations in 2024, will produce 4-nanometer chips, while the second phase, expected in 2025, will move to 3-nanometer production — the same process used for Apple’s M3 and A17 Pro chips.

As a result, Apple’s processors are now produced both in Taiwan and the United States, marking an important step toward a more resilient and geographically diversified supply chain.